Introducing Students to Nanofabrication

By Krista Burns

Media InquiriesToday's computer chip fabrication process requires specific and expensive technologies. From cleanrooms to highly specialized equipment, the making process of nanoscale technology prevents many higher education institutions from exposing students to the field. The Department of Electrical and Computer Engineering at Carnegie Mellon University has developed a hands-on introductory course that allows students to design and fabricate nanoscale technologies outside of a nanofabrication laboratory.

The current generation of commercial computer chips are manufactured in facilities upwards of $10 billion and require highly specialized training to iterate upon designs. It is rare that companies would allow scientists and engineers to experiment with these technologies. Known as the Hacker Fab, the primary goal of this new course is to enable students to fabricate computer chips by hand, and design DIY fabrication equipment in a nontraditional way.

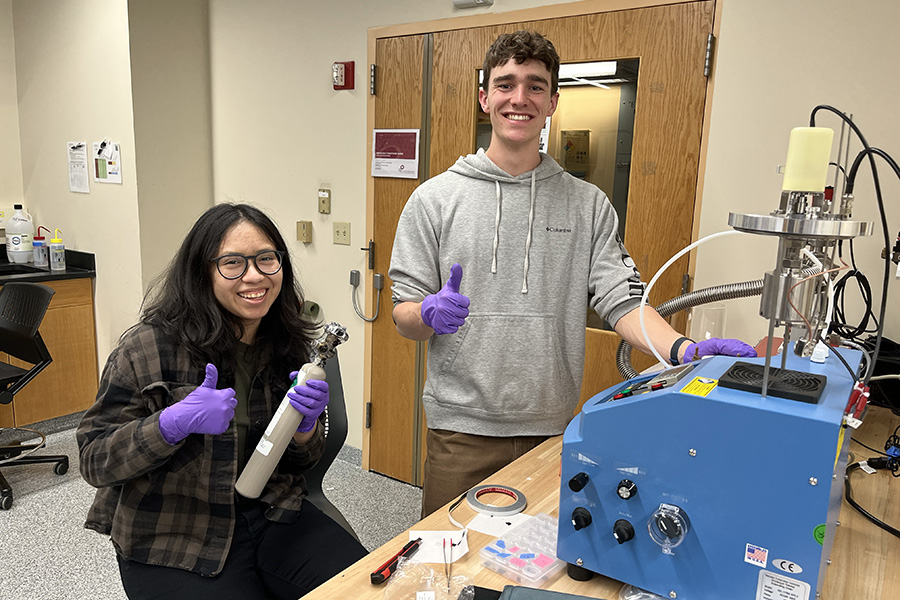

The course aims to develop plans, instructions, diagrams, and videos for a low-cost semiconductor fab suitable for teaching students how to make computer chips. In its inaugural semester, the class enrolled ten students spanning four engineering departments ranging from first-year to Ph.D. students.

“We are developing a blueprint on how to expose more students to computer chip fabrication,” says Larry Pileggi, the Coraluppi Head and Tanoto Professor of Electrical and Computer Engineering. “This is extremely valuable as we are seeing a push to bring computer chip fabrication back to the United States. This course will lower the barrier for many students, especially those who don’t have access to a cleanroom.”

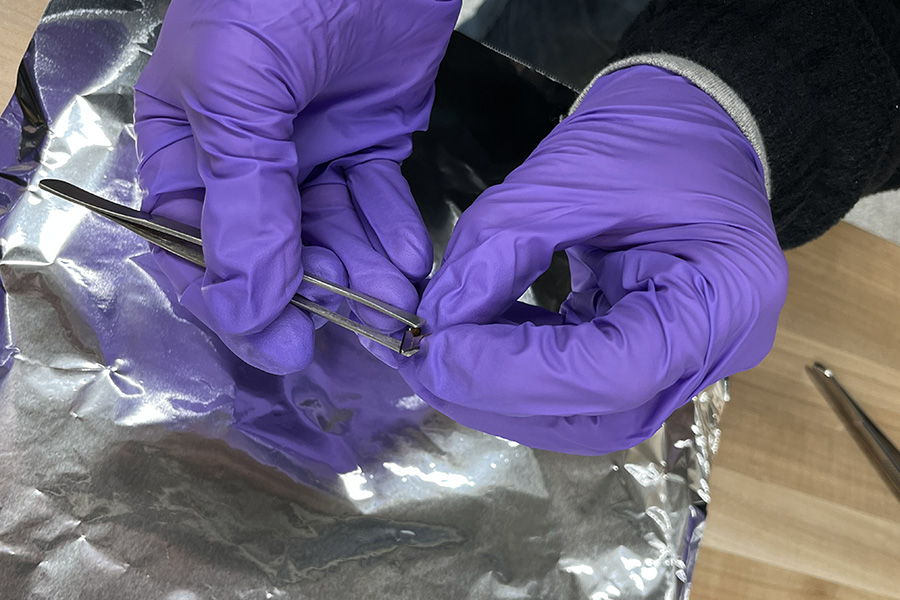

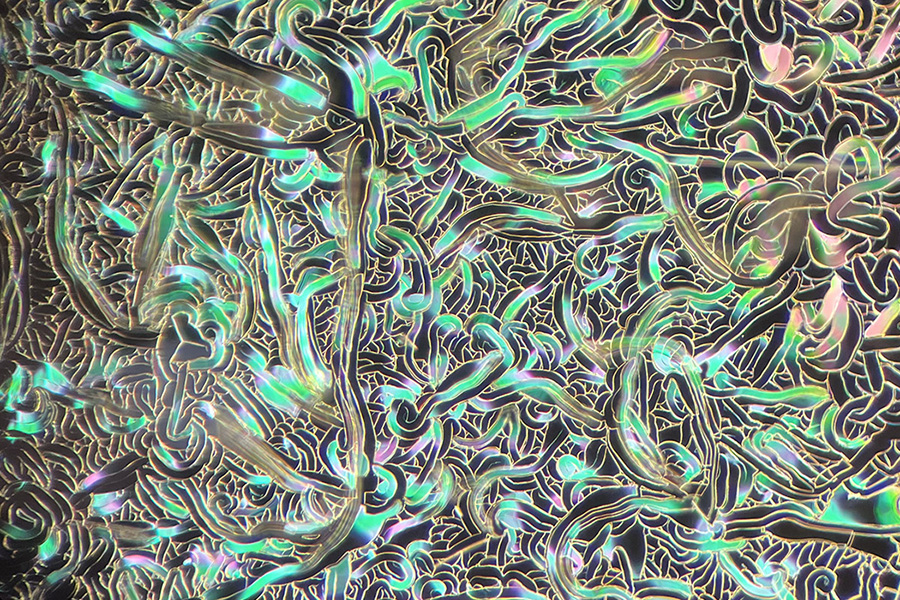

The Hacker Fab covers all essential nanofabrication topics, including deposition, patterning, oxidation, doping, inspection, metrology, dynamics/motion control, vacuum systems, optics, material selection, and plasmas. From the first day of class, students begin work to contribute to the central Hacker Fab open-source project. Lectures serve to aid students in their project work by covering the physical phenomena behind each process and the design and operation of the necessary tools. Students also apply lecture materials in weekly lab assignments to fabricate basic devices that include MOS capacitors, diodes, transistors, simple logic circuits, and more. There are no exams; instead, the vast majority of class time is spent making tangible progress on the larger open-source Hacker Fab project.

"The course outline should allow other universities, and eventually high schools or other organizations, to replicate this class," says Elio Bourcart, lab manager and engineering alum. "The course is completely open sourced with no IP licensing requirements. We emphasize high-quality documentation and development of a collaborative community among Hacker Fabs at other institutions that is self-supporting. We hope to leverage collaboration techniques from the open-source software world."

The Hacker Fab was inspired by ECE alum Sam Zeloof, whose groundbreaking work laid the foundation for this innovative course. Sam began making chips alone in his garage during high school. It provided the impetus for a larger project that could inspire a generation of electrical engineering makers in the same way that 3D-printing inspired an engineering maker movement.

“Elio and I are two mechanical engineers who began work on semiconductor fabrication just through being good friends with Sam and playing in his Garage Fab,” says Alexander Hakim, Hacker Fab co-instructor. “I hope we are a sign to not only encourage students that semiconductor education is interdisciplinary, but to show other institutions the breadth of potential student interest. By working with Hacker Fabs at other institutions in parallel, designs will rapidly accelerate towards the capabilities of more modern devices. We want students to know that their work reaches well beyond one lab at CMU.”

The team hit every milestone that they set out to achieve. In just one semester, ten students built the first version of the DIY lithography stepper and developed processes to fabricate functional 10µm transistors. Everything was documented to facilitate other schools to develop similar labs and courses.

While the course sits in the electrical and computer engineering department, it is open to all engineering students who are interested in hardware fabrication. By offering a wide range of open-ended projects, it is expected that the Hacker Fab will attract students from across the university in the coming semesters.

“When I heard that the electrical and computer engineering department was launching a new research initiative to build a lab capable of fabricating transistors, I knew this was something that I wanted to get involved with,” says Joel Gonzalez, a Ph.D. student in electrical and computer engineering. “As a student with interests in everything from integrated circuits to radio systems design, this lab seemed like a fantastic way to apply what I had learned to a project that would impact future students in our department.”

The course will enroll its second cohort this upcoming fall semester. Due to space constraints, only a limited number of students will be placed in the class. All students who register will automatically be placed on a waitlist and will receive an official application later this summer.

“We want to build a diverse team tailored to the projects we have planned for the semester,” explains Bourcart.

15 to 20 students will be chosen to join the lab this fall. Students can register for the Hacker Fab (18-469D) on SIO. A graduate class (18-669) will also be listed.